Dec 18, 2025Ixana Team6 min read

The 'Unboxing' Bottleneck: Why Logistics Needs a Portless NFE Data Link

The Hidden Cost of "Checking the Box"

In cold-chain logistics, the intake process remains a critical point of failure. While goods are monitored by data loggers sealed inside the packaging to ensure they remain within a strict thermal range, verifying that compliance creates a paradox: receiving teams often have to break the seal.

Current workflows frequently force workers to physically unbox cartons, cut through insulation, and plug a USB logger into a computer just to retrieve data. This "unboxing" bottleneck destroys thermal integrity, slows down intake lines, and introduces manual handling risks. Every minute spent unboxing a pallet for compliance checks increases labor costs and exposes the product to thermal excursions that account for a significant percentage of total cold chain spoilage.

The Wireless Gap in Warehousing

Why hasn't the industry already cut the cord? The problem lies in the limitations of today's standard wireless protocols. Logistics managers have generally been forced to choose between two imperfect options:

- NFC (Near Field Communication): While secure, NFC is strictly limited by range. It typically functions at 4 cm, making it difficult to communicate reliably through the thick insulation layers of cold-chain packaging. Furthermore, with a max data rate of only 0.4 Mbps, downloading weeks of granular temperature history becomes a bottleneck during high-volume intake.

- Bluetooth LE: In dense RF environments, characterized by thousands of tags, metal racks, and multipath propagation, BLE deployments often require careful channel planning and still face coexistence and interference issues. Additionally, its omnidirectional radiation pattern creates security vulnerabilities and drains battery life unnecessarily.

This technological gap has left the supply chain relying on manual connectors or compromising on data granularity.

The Solution: Sealed Intelligence with Ixana Wi-R NFE

To solve the "unboxing" dilemma, Ixana has introduced Wi-R NFE (Near Field Electric) technology, powered by the

XA-NFE2001 transceiver.

XA-NFE2001 transceiver.

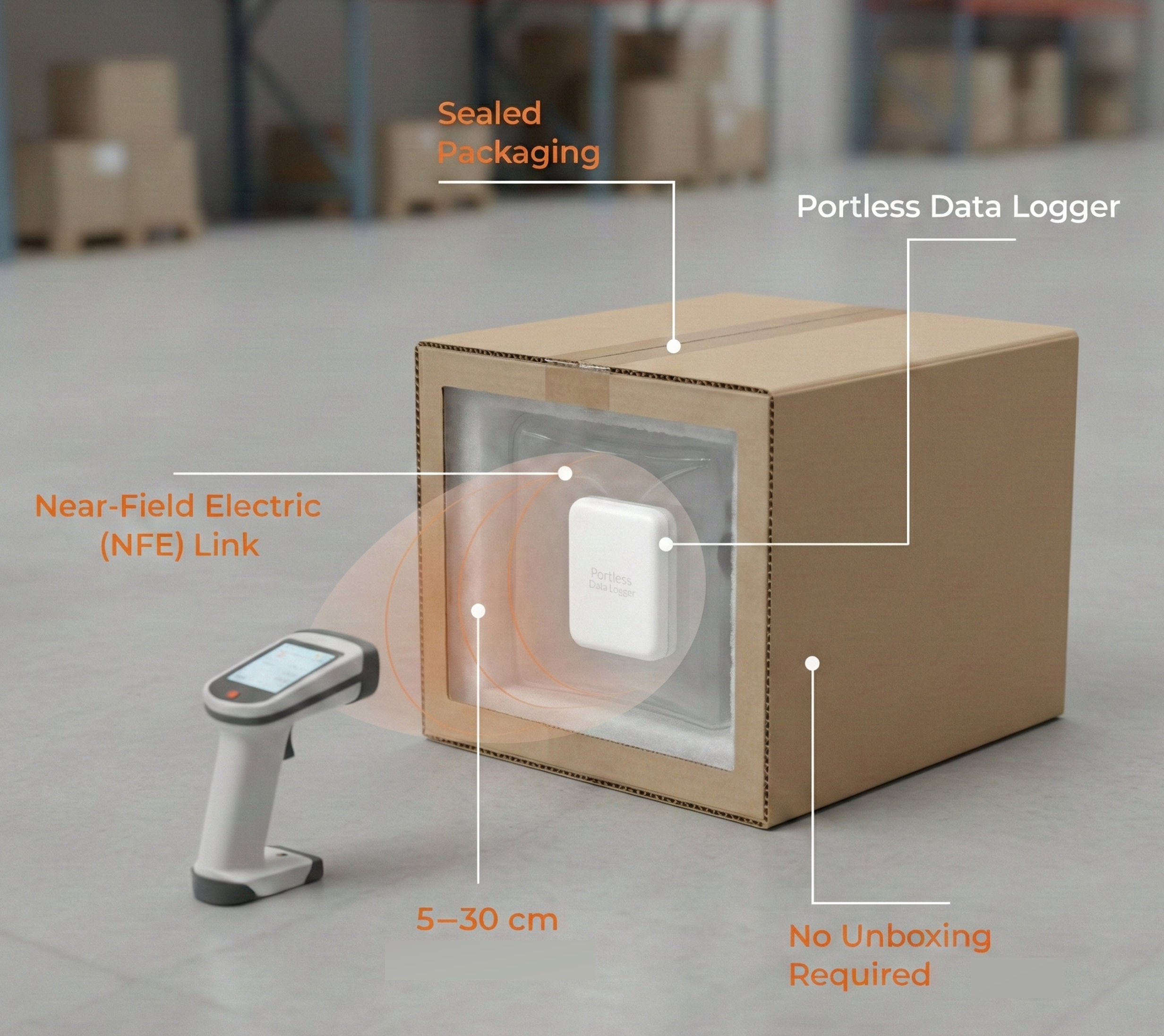

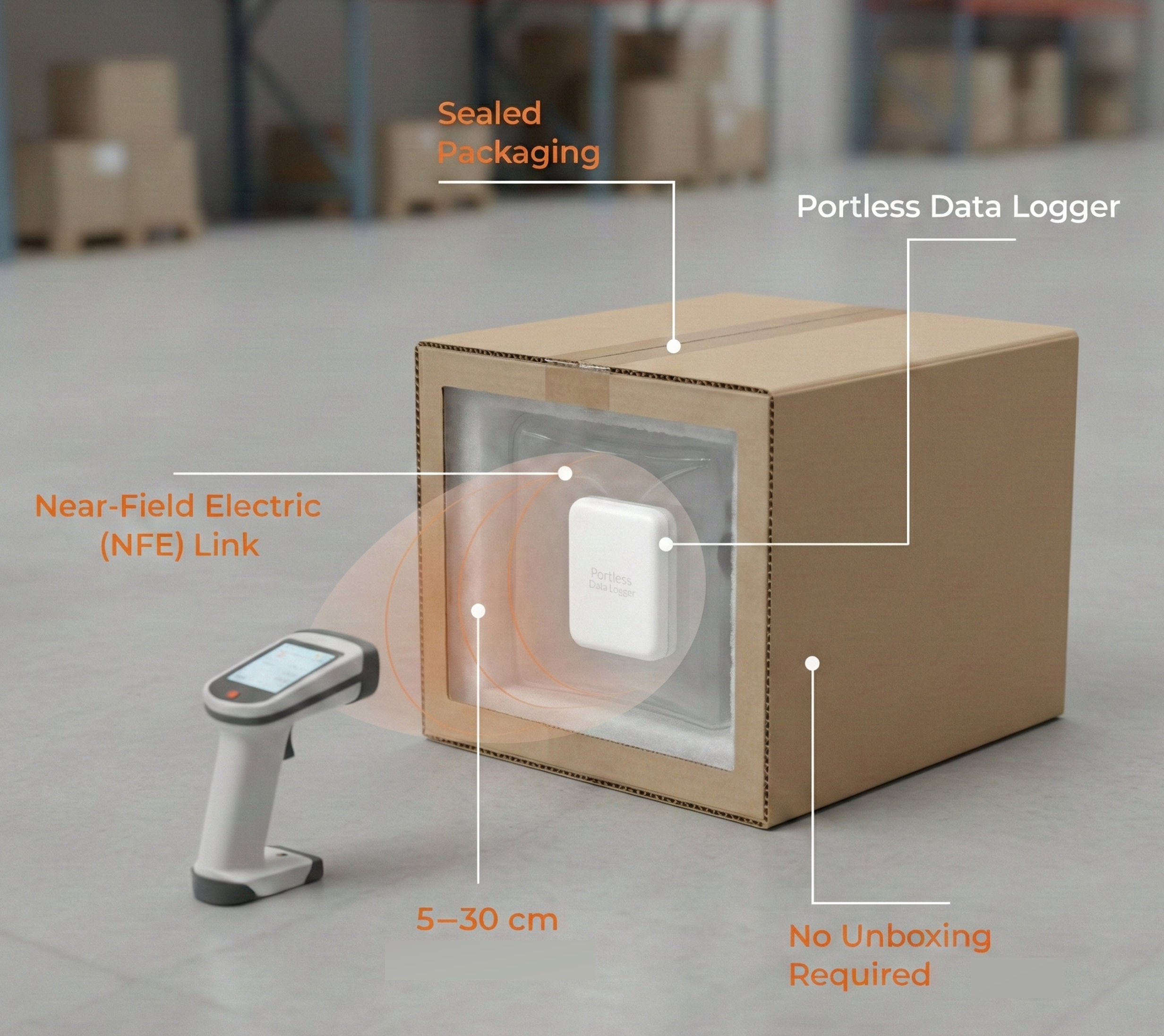

This technology is purpose-built to bridge the gap between sealed hardware and the outside world. Wi-R NFE uses capacitively-coupled electric fields to create a secure, high-speed data link. This allows reliable communication through plastic, thick thermal insulation, and cardboard packaging without requiring physical connectors or holes in the enclosure.

This capability unlocks a truly "portless" architecture for logistics. Receiving teams can simply tap or bring a scanner within proximity (typically 5–30 cm) of a sealed crate to initiate a link. Because the signal remains confined to the immediate vicinity, it creates a "private bubble" of connectivity that doesn’t leak data or suffer from the interference issues common in crowded warehouses.

The Mechanics: Speed, Power, and Scalability

Replacing the "unboxing" step requires a technology that outperforms existing standards on every critical metric. Wi-R NFE delivers the necessary performance to make near-touch intake a reality:

- High-Speed Data Offload: With a data rate of 5 Mbps, NFE is over 12x faster than standard NFC. This bandwidth allows workers to extract weeks of high-resolution temperature logs (e.g., 500 KB) in under one second, or transfer large firmware updates that would be impossible over NFC.

- Install-and-Forget Efficiency: The XA-NFE2001 operates at <1 mW during active 5 Mbps transmission-offering up to 100x better energy efficiency than Bluetooth. This efficiency isn't just about battery life; it enables a new class of logistics tags that survive the entire product lifecycle without recharging, with sleep modes enabling mission lives measured in months or years.

- Precision Scanning: Because NFE uses a confined electric field (approximately 18 cm radius in the XY plane), it eliminates cross-talk. The signal strength drops rapidly outside this boundary, allowing a worker to selectively scan a specific crate without unintentionally initiating a session/link with adjacent devices-a fundamental advantage over omnidirectional RF protocols.

- Multi-Device Scalability: Critical for warehouse throughput, the XA-NFE2001 SDK supports simultaneous communication with up to 16 devices. This allows receiving clerks to scan an entire pallet of boxes at once rather than processing them one by one.

Technical Integration

For decision-makers looking to upgrade their infrastructure, the XA-NFE2001 is designed for seamless integration.

Performance Comparison

| Parameter | Wi-R NFE | NFC | Bluetooth LE |

|---|---|---|---|

| Data Rate | 5 Mbps | 0.4 Mbps | 1–2 Mbps |

| Active Power | <1 mW | ~24 mW | 10–100 mW |

| Typical Range | 18 cm (configurable) | 4 cm | 10+ m |

| Interference | Minimal (confined field) | Low | High (dense environments) |

Integration into existing logistics hardware is simplified through the chip's SPI interface (up to 24 MHz) and compact 6×6×0.8 mm QFN packaging. With a wide operating temperature range of -40°C to 85°C, the XA-NFE2001 ensures reliability in extreme cold-chain environments.

The Vision: The Connectorless Supply Chain

The integration of Wi-R NFE signals the end of the "break-the-seal" era. We are moving toward a connectorless supply chain-an environment where receiving docks can verify compliance through near-touch coupling without a single box cutter being used.

By eliminating the need for physical connectors, manufacturers can build rugged, fully waterproof logistics tags that are cheaper to produce and harder to break. These "sealed intelligence" units can travel from factory to pharmacy, providing a tamper-proof digital chain of custody accessible only through a secure, proximity-based handshake.

Development kits for the XA-NFE2001 are available for evaluation.

Supply ChainCold ChainWi-RNFELogistics

Ixana Team

Developing ultra-low-power near-field wireless technology for the next generation of mobile and wearable devices